Category Archives: optics

Windshield Navigation May Become a Reality by 2016 – Augmented Reality with comments from Mark Zuckerberg

“Facebook wants to build the next major computing platform, which Zuckerberg believes could be augmented reality and Oculus. He also wants to bring the internet to more people through Internet.org.”

Read more: http://www.businessinsider.com/zuckerbergs-3-5-and-10-year-facebook-plan-2014-10#ixzz3HYbURZOM

Displaying navigation information on car windshields may become reality in less than a decade. If thin, transparent and curved display panels could be attached to a windscreen, drivers would be able to see navigation information displayed there.

There are challenges to this application, namely cost and durability. The inside surface of a windscreen (surface 4) takes abuse, such as parking stickers. This has been the main factoring for not using polycarbonate as the inner layer. Previously HUD worked with aid of a wedged Poly Vinyl Butyral (PVB), looks like that may change. Head-up displays make driver and vehicle information easily accessible by projecting it onto the windshield just below the driver´s line of sight.

Without taking the eyes off of the road, drivers are informed of important vehicle data, such as speed, engine warnings or navigation data. For its realization a wedge shaped PVB-film is necessary. The wedge shaped film avoids the formation of echo images. Those echo images are dependent on the angle and the thickness of the windshield as well as the angle of incidence of the beam.

Standard wedge angles are defined in order to avoid special developments for every type of windshield. For production of the wedge shaped film small flexible extrusion lines up to a film width of 1200mm are necessary. Colour band film is also available. The loss of thickness during the stretching process of the film has to be compensated in the production process. The related technology is expected to become commercialized by no later than 2016.

Recently, LG Display unveiled the world’s first transparent and curved displays. In order to use the display for windshields, these two technologies must be combined, so that the screen becomes both transparent and curved. The transparency also needs to be improved, she added. The new LG transparent OLED display features a transmittance of 30%, up from 10% for conventional LCD panels. But, to make the panel for car windshields, the transmittance rate needs to be pushed up to over 60%.

The world’s first flexible display developed by LG Display

This is not simple because most electrodes which are used for display panels are opaque. Currently, research is being carried out to find alternative materials such as graphene, which is transparent and conducts electricity.

There is also a visibility issue because users may not be able to clearly see the information displayed on the screen during the day, when it is brighter outside than it is inside the car.

Apart from the technical hurdles, safety issues still remain as the windshields would hinder the drivers’ visibility. This is why transparent displays for vehicles will first be used for entertainment purposes ― made for passengers in the back seat or riding shotgun, as I wrote about in a previous column

Regarding the visibility issue for the passenger seats, companies are developing a “shutter” technology, which is inserted into display panels to make the background black. This will have the same kind of effect you would have when you draw the curtains at home to get a clearer image on your TV screen.

According to sources, the global transparent display market will reach $87 billion by 2015.

Head-up displays with “augmented reality,” the technology that employs much of the windshield as a display area for data and images, is poised to significantly change how drivers see the road.

Auto supplier Continental AG says it has lined up a production contract to supply its new HUD technology for an unnamed customer in 2017.

It allows you to have your eyes constantly on the road, You can travel blindly for quite a few meters.”

Suppliers use the phrase “augmented reality” to describe large, multicolor head-up displays that superimpose data or images across much of the driver’s field of vision through the windshield.

Companies such as Nippon Seiki, Harman, Visteon, Bosch, Panasonic, Delphi and others are developing head-up displays, and Denso has said it will market its own version of augmented reality.

Continental displayed its technology this month to reporters in a modified Kia K900 on public roads near Babenhausen, a town near Frankfurt where Continental designs and produces head-up displays.

For the motorist, the transition from a conventional HUD to augmented reality is like switching from a small, portable black-and-white TV to a big-screen TV.

There’s a big difference in image size, color and definition, and that allows engineers considerably more freedom to display useful data for the motorist.

Continental’s new unit is actually two HUDs packaged together. The first is a conventional unit that displays the vehicle’s speed, directions for the motorist’s next turn and a lane-departure warning.

The basic unit’s display floats about 8 feet in front of the motorist through the bottom of the windshield, a typical HUD position.

The second unit produces a virtual display about 25 feet in front of the motorist. When the navigation system indicates an upcoming exit, a series of virtual blue arrows floats along the route to be taken.

In addition to turn-by-turn information, the second unit displays a more elaborate lane-departure warning, collision alerts and highlights of cars on the road ahead that have been detected by the vehicle’s intelligent cruise control.

A major issue for market acceptance is the bulk of the optics box inside the instrument panel. The prototype optics fit inside a 13-liter container; Continental engineers say they will shrink the production version to 11 liters. A smaller, less expensive “combiner” HUD — which doesn’t require an expensive, custom-designed windshield — could prove to be the technology of choice for small vehicles. Combiner HUD images appear on a small, clear plastic panel mounted behind the instrument panel. These units can display basic information, but not the big, colorful images of the more expensive unit.

Augmented reality HUD has the potential to change the auto industry’s approach to instrumentation.

In Samsung’s design, see FIG. 20 noted above illustrates an example in which the transparent display apparatus is implemented in a vehicle. To be specific, the transparent display is implemented on the front glass of the vehicle. Moreover, patent FIG. 20’s information appears on the front glass while the user drives their vehicle. The information #30 noted as “Vehicle in front slowing down” is one example of a smart transparent display system. The types of information that could be displayed include condition of the vehicle, a driving condition, the surrounding environment, etc. For example, GPS information, fuel status, speed, RPM, traffic, or other vehicle information may be displayed on the front glass.

display of FIG. 20 may alternatively be implemented as a projection type of system. Another alternative could involve a secondary sensor may trace the gaze of the user and the position of displayed information that may be moved according to the user’s gaze.

Remember the stunning heads-up display shown on the amazing BMW i8?

Well, you can’t have it — at least, not yet — but several manufacturers are working hard to improve the humdrum HUDs that many of us rely on for mundane details like vehicle speed and remaining fuel. The latest such gadget to cross our desk is called Navdy.

There are several things to like about Navdy:

- For starters, its aftermarket, so nearly any kind of car can use it.

- It also uses a gesture-based control system, meaning that, with a little bit of trial and error, drivers should be able to interact with it without much problem.

- Navdy uses the apps that are already on your phone (Android and iPhone, for now). Navdy will allow you to control music, messaging, and more using the apps you already know and love. To minimize distractions, users have control over which app notifications appear and when, and parents can block certain apps and features when kids are behind the wheel. Navdy is developing more apps in house to augment the device’s functionality.

- Navigation looks especially nice and useful.

That said Navdy isn’t without its flaws:

- At a retail price of $499, it’s expensive.

- It won’t ship until early 2015

- It uses Bluetooth

Glass will soon be accessible for the drivers on their windscreens of their cars. This innovation is for professionals, who want to remain connected while driving as well. Earlier, the time spent driving could not be utilized for work and hence got wasted, but now this new technology would allow the users to focus on the road while driving and at the same time be able to pay enough attention to their work, as well.

The idea of facilitating work while driving has been brought by a San Francisco-based start-up Navdy that has unveiled Google Inc. For this, the company has designed an aftermarket console that has the capability of combining a projection display with voice and gesture controls. This system is designed to find place between the steering wheel and the windshield. At a distance of nearly six feet from the windshield a transparent image is projected by this system.

The technology called Navdy HUD (Head-Up Display) system is designed to facilitate connectivity of iPhone and android devices via Bluetooth and sharing of data via WiFi. It also provides navigation services by connecting with Google Maps and displaying the projection on the windshield. If by chance a call or message is received while using the navigation service, the screen will split into two-parts with each part displaying one of the two. While the calls can be easily taken by giving thumbs up and hung up by swiping through the windshield, messages can be read aloud to the driver.

The system is compatible with all the cars manufactured after the year 1996, and offers multiple features such as displaying the car alerts including speed, miles-to-empty and battery-voltage. The users can, also, enjoy numerous other services such as Spotify, Pandora, Google Music and messages from the social media sites, but cannot scroll through the Facebook news feed with the Navdy HUD system.

Navdy is a device that will project virtually everything you now get on your mobile device onto the windshield of your car. Think of the windshield becoming a virtual movie screen that shows navigational data from your GPS unit, incoming phone calls, text messages and more. It responds to voice commands and gestures.

Navdy is reported to have racked up $1 million in pre-orders by discounting the device, which the San Francisco-based company later intends to market for $500. Connect it to your iPhone or Android and you’ll never have to reach for them again while you are driving. As Navdy’s marketing puts it, “No more looking down to fumble with knobs, buttons or touch screens.”

The company calls its product “The future of driving.”

While Navdy advertises itself as an antidote to distracted driving, the Internet was roiling Monday with voices challenging that. Streetsblog called it a “Scary new app.” James Sinclair’s blog at Stop and Move elaborates on those fears:

“When we’re focused on reading text, the world in the background may technically continue to be perfectly clear (as our eyes aren’t limited in focusing like cameras are), but that doesn’t mean our brain is processing it. In reality, it’s just as blurred because we’ve stopped paying attention to everything but the text. Go ahead, look at the image above and read the message — that’s all you really see.”

“Navdy may be safer than having a phone in your lap and looking down at it, but it doesn’t mean it’s a huge improvement. In fact, by making the distractions even more accessible, it might just mean more dangerous results. When your phone vibrates, you can choose to ignore it, when your new message pops into your windshield, showing that restraint becomes a little more difficult.”

The projected text message Navdy uses in its advertising is rather benign, Such as “Want to meet for coffee?”. While pondering a cup of coffee, the driver might notice that bicyclist to the right and the San Francisco trolley car up ahead. But what if the text was something more risqué, like, say, “I want to tickle your ear with a feather boa?” No distraction there?

The concept isn’t exactly new. In fact, Land Rover bragged that all of the glass in its Discovery Concept Vision, which debuted in New York earlier this year, would be “Smart Glass” capable of displaying images, directions, and point of interest (POI) information to passengers.

Though Land Rover spoke of this technology in virtual concept form, Jaguar taken the tech one step further and announced that its new XE sedan with offer a laser-projected Head-Up Display, providing drivers with unprecedented augmented reality information about the world outside the car.

https://www.youtube.com/watch?v=rP7x63f7ecQ

The system will project sharp, high-contrast images on the windshield using a device that is smaller and lighter than today’s HUD projectors. These laser diodes will contribute to a larger field of view with higher contrast and an extended range of reproducible colors.

The Land Rover Discovery Vision Concept is perhaps one of the most important and impressive vehicles I’ve ever covered. It uses lasers. It has touch screens, everywhere. Heck, it is a touch screen. It knows where you’re looking and puts information there. It can be driven remotely. And that’s just the beginning.

Vision technology

Not only does the Discovery Vision Concept have a “Transparent Hood” which uses cameras and augmented reality to make the hood disappear during off-road and parking scenarios. It is also capable of displaying images; every single piece of body glass – including the panoramic moon roof – is as well.

Called “Smart Glass”, the entirely transparent glass can display images just like a computer screen. This allows for all kinds applications. Perhaps most exciting is combining eye-tracking sensors and navigation information to relay point of interest (POI) information to passengers.

The Smart Glass can be used for more than just data. It can also be used to tint and dim the interior, with infinite gradients – or just blacked-out with the swipe of a finger. Imagine, too, using the panoramic moon roof to display a screensaver image or mood lighting. This isn’t the only use of screens in the cabin. Two small OLED screens are embedded into the steering wheel and can be used to operate the infotainment system. Glance through the steering wheel and the driver is privy to a digital instrument cluster on a three-million pixel high-res screen. In the center of the cabin are two more high-res touch screens, which display system menus. The lower of the two screens flips up to reveal a storage cubby, which also includes an inductive smartphone-charging tray.

The Japanese semiconductor supplier Nichia Corp. has announced development of blue and green laser diodes that it says are specifically designed for automotive HUDs. The laser diodes are slated for production in October, 2015. According to Nichia, these laser diodes will contribute to a larger field of view with higher contrast and an extended range of reproducible colors.

The Future Now

As I wrote in a previous column, General Motors has been working on a new generation Heads up Display system as well. There are many ideal vehicles to set to utilize developing technology by General Motors Research and the students from Bezalel Academy of Art and Design in Israel.

GM previews augmented-reality windshield

https://www.youtube.com/watch?v=94dg2D-jAhM

Whichever carmaker rolls it out, using components from whichever suppliers, there is much more to come. To bridge the gap from a simple HUD projecting rudimentary data ahead of the driver to full augmented reality, a few technical improvements are needed.

Glass Engineering: Design Solutions for Automotive Applications

Receive my first royalty check for my book today. Thanks to all who supported me. Sales have been strong.

http://books.sae.org/r-433/

Designing GLASS for Style – Polycarbonates

Designing GLASS for Style – Polycarbonates

Polycarbonates

Glass is not the designer’s only option to glaze an opening. Lightweight materials may find exciting opportunities in the automotive industry as a means of increasing fuel efficiency. With 75% of fuel consumption relating directly to vehicle weight, potential weight reductions that result in improved price-performance ratio promote use of lightweight materials. One of the key plastics used in automotive sector is polycarbonate (PC). PC has dominated the market for vehicle headlamp covers for 15 years, and now it challenges glass in windows. Plastics are lightweight materials ideal to improve fuel efficiency and design flexibility without compromising on performance or safety. The automotive industry can expect an impressive 6-8% improvement in fuel usage with only 10% reduction in vehicle weight. This translates into a reduction of around 20 kg of CO2 per kilogram of weight reduction over the vehicle’s lifetime. With newer advances in plastics materials, the weight of these parts is bound to reduce. Lighter vehicles facilitate easier braking, reduced collision impact overall vehicle performance and superior driving experience.

What is polycarbonate?

Polycarbonates are a particular group of thermoplastics. They are easily worked, molded, and thermoformed; as such, these plastics are very widely used in modern manufacturing. They are called polycarbonates because they are polymers having functional groups linked together by carbonate groups in a long molecular chain.

Polycarbonate is a very durable material, and can be laminated to make bullet-resistant “glass”. This polymer is highly transparent to visible light and has better light transmission characteristics than many kinds of glass. The primary advantages of polycarbonates in automotive glazing are lowered weight and associated CO2 emissions reductions along with greater styling freedom and simpler functional integration. The wide choice of styling options with polycarbonates is testing conventional assumptions of automotive window design and creating whole new opportunities for advanced vehicle styling.

Polycarbonate is becoming more common in industry. It is often used to create protective features, for example in banks as well as vandal-proof windows and lighting lenses for many buildings. Other products made from polycarbonate include sunglass/eyeglass lenses, compact discs, DVDs, and automotive headlamp lenses.

PC auto glazing permits parts integration previously not possible. Features such as colored glazing for tinted sunroofs and windows aft of the “B” pillar are now possible along with gaps in the window, sharp corners, smooth corner radii or complex three dimensional shapes. These features are undesirable, unmoldable or cost-prohibitive with laminated or tempered glass. PC auto glazing permits parts integration previously not possible. It is possible to create a roof-module frame and optical panel in one piece.

Fiskar Karma Atlantic 7

Molding heating/defrosting elements and fractal antennas into a PC window panel is also possible using in-mold films with preprinted circuitry. This is a versatile material to use, but advances in this application have been slowed by UV sensitivity of the material and its tendency to scratch easily, which makes it less weatherable than glass. If your production run is niche and well-funded, and you are looking to distinguish yourself from your competition, by all means, look at it. This is one material that is position specific. Legally it cannot be used everywhere, it is very expensive once it has been made fully coated for the durability cycle demanded of commercial use, usually 10 years.

The designer must now ask him or herself “What is my total cost versus what can be gained in mass reduction and design freedom?” The main drawback to a PC is weathering, resistance to scratch and scuffing. By the time you apply a hard coat, any potential savings derived from weight is now lost due increased piece price cost which can be as much as 4:1. There are infinite number ways that Design (Styling/Industrial Design) and engineering can and should work together upfront in the process. This can be used in the fixed vent window of, let’s say a Ferrari or framed sidelites for the XL1.

It saves weight, becomes a unique feature, like carbon fibre, but is unrealistic in normal production due to cost vs. value. Value still must be derived.

The Volkswagen XL1 uses polycarbonate windows to help save weight, just one of many distinguishing features

The Volkswagen hybrid concept, XL1 plug-in is one such vehicle that makes use of the innovative automotive lightweight solutions mentioned. The Volkswagen XL1 becomes the first vehicle to feature advanced plasma coating technology on two-component (2K) injection molded PC windows. Using polycarbonate resin, which is an amorphous engineering thermoplastic, characterized by outstanding mechanical, optical, electrical and thermal properties, Volkswagen reportedly estimates a reduction in weight in previous all glass applications at 33%, while delivering a high-quality optical appearance and scratch-resistant surface.

The ability to create an aggressive curvature of the upper portion of the sidelite adds to form and function. Since the upper lite is polycarbonate and stationary there are no additional abrasion issues due to traveling between a door moldings or packaging issues with getting the glass in a confined opening like the door inner and outer envelope. The occupant will generally not depend on that area for general viewing.

Looking at the XL1’s fixed and roll-down side windows pictured above, notice that the sidelite is two separate glass lites. The smaller of the two lites is glass and dynamic. The larger stationary lite is framed polycarbonate on its periphery to provide its structural integrity. This is because a polycarbonate side window will billow like a sail once the vehicle is mobile if not supported. The frame around the window adds rigidity, but also adds weight.

Looking at the XL1’s fixed and roll-down side windows pictured above, notice that the sidelite is two separate glass lites. The smaller of the two lites is glass and dynamic. The larger stationary lite is framed polycarbonate on its periphery to provide its structural integrity. This is because a polycarbonate side window will billow like a sail once the vehicle is mobile if not supported. The frame around the window adds rigidity, but also adds weight.

The requirements for plastic glazing are met by depositing plasma coating on the parts after molding. This glass-like plasma coating, applied over a hard coat, delivers enhanced weathering, durability, and abrasion performance and enables compliance with global requirements and regulations for plastic glazing applications.

Wet coating

Federal regulations prohibit the use of polycarbonate in an AS1 position (windshield). Federal regulations further state, for these positions must demonstrate the ability to meet ≥ 70% Light transmission (LT) for AS1 (Windshield) and AS2 (Sidelites) applications. In 2005, the U.S. Dept. of Transportation’s National Highway Traffic Safety Administration (NHTSA) confirmed that polycarbonate may be used in vehicle areas specified for Item 2 (AS2, AS3) glazing (safety glazing material for use anywhere in a motor vehicle except windshields), provided that the product satisfies the existing performance standards for Item 2 glazing. Questions persist regarding retention of the necessary transparency over the useful lifetime of the vehicle. A test has been developed for coated polycarbonate automotive glazing to measure their resistance to windshield wipers. This test enables simulation of the actual stress exerted on the wiped glazing far more realistically, accurately, and with a higher reproducible quality than is possible with the Taber abrasion test stipulated in the regulations. Initial tests have shown that, when dirty panes with a polysiloxane coating are wiped under primarily wet conditions, they exhibit virtually no clouding that is visible to the naked eye – even after 30,000 double-wiper cycles.

Wiper performance is critical in the design, engineering, and testing acceptance of a windshield for a saleable vehicle.

PC glazing technology continues to enable the development of advanced, lightweight window designs for the automotive industry. Polycarbonate glazing may enable weight reductions up to 50% versus comparable glass materials, depending on the complexity and design of the window part, but as you saw with the XL1 33% will probably be the realistic range.

Toyota’s two-panel Prius V moonroof made of polycarbonate plastic.

In conclusion; Polycarbonate is sneaking into the western auto industry as glass replacements in non-strategic areas. Hyundai has used it on concept cars and Bugatti on a new lightweight targa top for the Veyron (saving 13 pounds).

Bugatti Targa top

The most prominent mainstream users of polycarbonate right now are Mercedes (which puts it into fixed Smart side windows, as well as those roof panels) and Toyota, which is introducing it on the V, the new station wagon version of the Prius.

General Motors also introduced it in the concept Chevy Volt roof panel.

New legislations in Western countries have been introduced to limit pollution caused by vehicles. European legislations such as EC 715/2007 (Euro 5, 6 standards) and U.S. regulations such as EPA 2010 are applying stricter rules to reduce CO2 emissions from new cars. The United States government announced a plan to increase fuel efficiency by more than 5% pa starting in 2012. These requirements necessitate lighter vehicles and improved fuel efficiency. European regulation currently permits polycarbonate (PC) use in all automotive glazing applications except the windshield. In the United States, the US Department of Transportation’s National Highway Traffic Safety Administration (NHTSA) has approved the use of PC for all non-windshield glazing applications provided that it meets all existing auto glazing specifications for laminated glass as prescribed in the Federal Motor Vehicle Safety Standard (FMVSS) No. 205. This includes < 2% delta haze in the all-important Taber 1000 abrasion test. However, uncertainty over long term weathering and compliance with the ANSI regulation has held back adoption of PC glazing in the US.

Technical data on polycarbonates

Polycarbonate has:

Density = 1.20 g/cm3

Use range from -100°C to +135°C

Melting point around 250°C

Refractive index equal to 1.585 ± 0.001

Light transmission index equal to 90% ± 1%

Poor weathering in an ultraviolet (UV) light environment

SAE International – This week is ‘Glass week’

Are you interested in learning about automotive glass engineering? Check out the new book, “Glass Engineering: Design Solutions for Automotive Applications”!

A virtual windshield developed by Jaguar Land Rover

Not satisfied with displaying information relative to speed or the navigation system only, British manufacturer Jaguar Land Rover has decided to push the idea of information being displayed on a windshield to a level that would give a video game a run for its money.

Head-up display thus takes on a whole new meaning with the virtual windshield developed by Jaguar Land Rover which transforms a vehicle into a learning tool for driving on a track. Just like a racing video game, the windshield displays the ideal trajectory for negotiating a winding road or track, in addition to displaying the lap times. Information relative to other drivers driving on the circuit are also displayed.

The windshield can also display virtual cones to form a slalom. A “ghost car”, a virtual car that appears on the screen and helps compare driver performance by representing the position of the vehicle at the last passage could also be presented on the virtual windshield.

Although the main focus of this new technology is to help drivers hone their driving skills on the track, the virtual windshield could also theoretically help young drivers. For example, the windshield is able to indicate the braking force required and when the brakes should be applied before reaching a given turn.

Like the transparent hood developed by Land Rover, the virtual windshield is an embryonic technology. One should therefore not expect to see it on production models in the near future, but it remains unique and its applications are numerous.

Thanks to Journalist

Glass Engineering: Design Solutions for Automotive Applications

Glass Engineering: Design Solutions for Automotive Applications

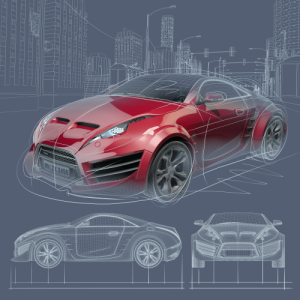

Designing Glass for Style -Characteristics of Automotive Glass

Please go to: http://www.autodesignclub.com/ for the full article

Please go to: http://www.autodesignclub.com/ for the full article

(Design Schools/Educators)

Characteristics of Automotive Glass

The worlds glazing manufacturers are constantly striving to deliver products that provide the best possible technological solutions to meet automobile manufacturers’ and end-users’ needs from a comfort, safety and security perspective, whilst at the same time helping the industry to meet its climate commitments.

Safety and Security

Glass plays an important role in a car’s ability to offer safety and security to its occupants. The automobile industry is ever increasing its use of laminated glass, which is literally a “sandwich” of two glass sheets with a thin but resilient plastic layer between them. This plastic layer is polyvinyl butyral or PVB. It can be made in two variations, standard and acoustic. Laminated glass can now be found in sidelites and in panoramic roofs on intermediate priced automobiles as well as luxury offerings. The layers are bonded to each other under controlled heat and pressure by using an autoclave.

If the glass suffers an impact, the glass layers may fragment but, depending on the force of the impact, the plastic interlayer will hold. This type of construction is mandated for windscreens and is becoming increasing popular in sidelites for sound attenuation. This safety feature enables the vehicle to absorb some of the energy of the impact and helps to prevent the ejection of the driver and passengers and the penetration of objects in case of an accident. Moreover, after an impact the resulting glass fragments tend to remain attached to the plastic interlayer, reducing the hazards of sharp projectiles during an accident. And the fact that windows made of laminated glass will tend to remain in their frame greatly improves the performance of the side airbags, providing the necessary support during inflation.

The #1, 2, etc. are surface designations. #1 is the outside or class ‘A’ surface, #2 is the surface adhering to the PVB, and same with #3, #4 is the surface inside the cockpit/cabin.

A different kind of passenger safety factor is provided by UV (ultraviolet) filter glass, which blocks harmful UV rays to protect skin and eyes (as well as the materials of the car’s interior). UV filter glass blocks >99% of harmful UV rays from entering the vehicle, keeping the driver and passengers’ safe and greatly extending the life of upholstery and fabrics. UV filter technology can be incorporated into laminated glass for optimal safety and security.

Visibility and Visual Comfort

Good visibility conditions are critical to driving safety, and visual comfort (for example light reflections and glare) is part of visibility. The driver’s field of vision is influenced by the light the windscreen allows into the cabin. Indeed, bright sunlight causes glare, rain smears the windscreen, condensation clouds the view and ice buildup blocks out almost everything. Today’s vehicle glazing technologies can deal with all of these. Windshield installation angle plays a significant part in glare, specifically veiling glare, which is the reflection of objects on your instrument panel.

This is mitigated to great extent by having the instrument panel (IP) top cover, one color; Black. Black absorbs, and does not reflect, it also enables the automaker is carry only one part number in their system, and reduces the complexity of inventory control. This also eliminates matching the various vehicle interiors.

Anti-reflective Glass

Reflections on the inside of the windscreen can disturb the visual comfort and concentration of the driver. This is compounded by lighter IP top covers that may still exist. Anti-reflective glass, which is treated with a special coating, can reduce these reflections by up to 40% at a reflective angle of 60 degrees, and also helps reduce glare. Reduces exterior and interior visible light reflectance to less than 2%

- Transmits more than 90% visible light

- Superior safety, security and acoustic performance

- Blocks over 99% of UV transmittance

- Durable pyrolytic (hard coat) surface, bendable and temperable

Hydrophobic Glass

In the field of Nanotechnology, hydrophobic coated glass is often used in automotive and applications. Hydrophobic glass is coated with a polymeric layer that repels water, causing rain or other water to run off the glass without leaving droplets and also greatly improving the effectiveness of windshield wipers in completely clearing water from the windscreen. This leads to significant increases in visibility under wet conditions due to less surface contact with the glass. The early claims from the suppliers were that it would eliminate the use for windshield wipers. This would never be proven successful.

Hydrophilic glass is characterized by a contact angle of ≥105°, whereas Hydrophobic is ≤90°

Heatable Glass

Electrically heated glass was first developed in World War II to prevent aircraft windscreens from frosting over and obscuring visibility. Since then, this technology has been become almost universally used in aviation. It has even reached supermarket freezers, where glass doors must remain clear for customers to be able to see the merchandise. In order to electrically heat glass, a microscopic Tin (II) Oxide coating is applied to a pane of ordinary float glass. This coating is perfectly transparent and conducts electricity. An electrical current is supplied by two busbars located on opposite sides of the glass. The electrical resistance of the Tin Oxide coating produces heat energy. This heat radiates from the glass in the form of infrared energy. The busbars are typically connected to a power control unit that regulates the flow of electricity and thus the temperature of the glass, much the same as your backlite defogger/defroster system.

Electrically heated glass maintains a steady and consistent temperature across the entire surface, and heat radiates off the glass in only one direction: toward the object or area to be heated. In addition, this technology imparts beauty and elegance to glass. The glass can also be coloured or etched with designs in order to complement the appearance of a room or appliance. At one time the Corvette looked at having the grid pattern created to look like the Chevy ‘Bow Tie” symbol.

Electrically heated glass is a laminated glass, incorporating almost invisible electrically-conductive wires. It comprises two or more sheets of glass interlaid with one or more films of polyvinyl butyral (PVB). This assembly combines comfort with safety, whilst preventing condensation. Electrically heated glass is suitable for any circumstance where there is high moisture content in the air and where the difference between the internal and external temperature may lead to condensation risk. In heatable glass, invisible wires or an invisible metallic coating, in each case embedded into the interlayer of the laminated windscreen, respond to an electrical charge by raising the temperature of the glass, in cold weather speeding the removal of any condensation or ice and then of course preventing any further condensation or ice buildup. The potential failure mode to embedded wires is moisture intrusion and delamination. Depending on how quickly the elements heat up, there is always a risk of thermal shock which could lead to windshield a failure mode.

Thermal Comfort

Today’s increased use of glass in automobiles means that, without the right technologies, more solar energy will penetrate the interior of the vehicle, causing high temperatures. For example, when the outside temperature is 80.6°F/27°C, without anti-heat technologies, a car interior can heat up to 136.4°F/58°C in few minutes. Combating this solely by way of air-conditioning alone would be an environmentally unfriendly approach, leading as it would to higher fuel consumption and CO2 emissions.

In recent years, the industry has developed solar control glazing. This type of glass is specially engineered to reduce vehicle cabin by up to 44.6°F/7°C or 46.4°F/8°C temperature, and reduce heat penetration in vehicles exposed to solar radiation by over 25%. In this way, a significant amount of energy is saved from powering air-conditioning units while passengers’ comfort is safeguarded.

Solar control glazing

Solar control glazing has a coating that allows it to reduce the transmission of solar heat from the external environment while still permitting the optimal light transmission essential to ideal driving conditions. This type of glazing can reduce by over 25% the heat penetration in vehicles exposed to solar radiation, thus reducing the need for the use of fuel-hungry cooling systems. Dark-tinted glazing and switchable glazing also have solar control properties which can reduce the amount of solar heat entering the vehicle’s cabin.

The last decade has seen significant improvements in the design and application of solar control glazings in vehicles. The major drivers are passenger comfort, minimising the degrading effects of the sun’s radiation on interior trims and fabrics, and improving fuel consumption by lowering the load on the vehicle’s air-conditioning unit. Additionally, vehicle styling is impacted by the choice of solar control glazing, from dark tints in the rear of the vehicle, to the differentiated colour of infrared reflective windscreens.

Solar radiation is partly reflected, partly transmitted and partly absorbed by a glazing, the degree of each depending on the glazing fitted. Most tinted glasses can selectively absorb the sun’s energy, whilst glazings with specially designed coatings can be used to reflect solar radiation.

Absorbing Solar Control

Green optimised solar absorbing glasses are providing significant improvement to occupant comfort. The products, designed for the European and North American markets respectively, reduce the heat entering through a vehicle’s glazed area by roughly 20% when compared to a car equipped with standard tinted glass.

Due to vehicle safety legislation, requiring adequate light to provide clear driver vision, use of these dark tinted glazings is restricted to rear passenger compartments and to roof glazings.

The privacy glazing segment, originally developed for the North American market, now finds global applications. This grey glass has a low light transmission and an even lower transmitted energy value. It reduces the transmitted heat to the interior of the vehicle by approximately 65% in comparison to an optimised green glass used in the front of the vehicle. It also prevents more than 95% of ultraviolet radiation from entering the passenger compartment. This glass is increasingly the choice for SUVs and MPVs, in addition to being suitable for roof glazing applications.

One particular manufacture makes a green/blue portfolio of glasses that blends with the green front door glass to allow both a design choice and an improvement to solar loading. The glass has a light transmission in the range 26-45 % over a 3-5 mm glass thickness range. In a vehicle equipped with this technology the heat entering the rear of the vehicle is reduced by 45% when compared to that at the front of the car.

Reflective Solar Control

Many glass manufactures possess the technology and capability to deliver a coated windscreen product that reflects more than 30% of the sun’s energy (more than five times that of a standard glass). This particularly benefits the new generation of vehicles that are commonly designed with larger glass areas. In addition to coated glass product, automotive glazing also reflects the sun’s heat. Some products are constructed from an infrared reflecting film, laminated between two pieces of glass. The product can be used in all vehicle apertures.

Acoustic Comfort

Acoustic laminated glass technologies have been developed to combat levels of noise penetration in vehicles. Noise mainly comes from the sound of the car’s engine, air and other environmental factors (e.g. other cars, roadworks, etc.). When using specific acoustic laminated glass, an improvement of some 3-5dB can be achieved, which is quite noticeable to the ear. Lower noise levels mean that the driver will become less tired, and make communication inside the vehicles more comfortable, thus contributing to overall safety.

Acoustic glazing

Today’s automotive engineers are on an unending quest to make vehicle interiors quieter and more comfortable. In the auto industry, this translates to reductions in noise, vibration and harshness, or NVH.

Tests show noise is transmitted through the vehicle’s glazing and comes from several sources:

• Air-pressure fluctuations against the windshield at highway speeds

• Air impinging on the edges of the vehicle’s body panels

• Other vehicles and environmental noise

• Road noise and vibration; this is also transmitted through the body structure.

One way to reduce noise is to increase the thickness of the glass. This provides marginal noise reduction and adds weight to the vehicle. This decision will also impact the run channel and overall packaging space if the intended use is a door. The complete packaging envelope may change. A new power unit may be needed to accommodate the added weight. A windscreen is better addressed by an asymmetrical application with an acoustic graded PVB.

More recently, PVB suppliers have developed vinyl with improved acoustic-damping qualities. These new interlayers are particularly efficient in the 1,500 Hz to 5,000 Hz frequency range.

The decibel reduction typically is 2-3 dB overall. Although not large, it results in a quieter vehicle interior that allows people to converse without shouting.

Acoustic vinyl also enables vehicle designers to decrease the thickness of the windshield without negatively affecting noise levels. This is particularly important as automotive engineers try to shave weight off vehicles to make them more fuel efficient. Acoustic vinyl windshields meet all of the same federal safety specs as regular vinyl.

Acoustic vinyl is also suitable for use in sidelites to further improve interior noise levels. Other benefits include:

• Security or theft deterrence. It takes longer to break through a laminated glass window, therefore reducing “smash and grab” theft.

• Improved health. Laminated glass allows for lower ultraviolet light transmittance, especially beneficial to those with melanoma.

• Interior protection. Lower UV transmittance helps preserve vehicle interiors and slow color fading.

• Vehicle weight reduction. The vinyl interlayer’s lower density allows vehicle designers to maintain the same overall window thickness while reducing the weight of the window compared to monolithic tempered glass.

The main downside to the use of acoustic vinyl is its cost. However, the difference in cost between acoustic vinyl and regular PVB will likely diminish as volumes increase. There are 18 vehicle makes and 40-plus models sold in the United States with acoustic windshields. The types of vehicles sporting acoustic windshields stretch across all sizes and price ranges; their use is not limited to luxury vehicles. In fact, the 2008 Ford Focus compact car will have an acoustic windshield as standard equipment. These windshields also are available standard on Ford Escape, Mariner, Expedition, Navigator and Lincoln MKX vehicles.

Acoustic glazing consists of two or more sheets of glass, bonded together with one or more acoustic interlayers. The interlayers act as a noise-dampening core, weakening the sound as it travels through the glass. Acoustic laminated glass also benefits from all the safety and security properties of standard laminated glass. Moreover, acoustic windscreens reduce the need for heavier glazing, which allows car manufacturers to reduce vehicle weight.

*This will not affect commercial trucks where the need is more in mitigating the damage from stone impingement than noise. This is achieved by using an asymmetrical windshield.

Reducing the noise level of a vehicle cabin is an important factor for passenger comfort. It is also important for safety concerns because noise is believed to reduce driver efficiency over time. Sound transmission loss through a glazing system can be induced by mass, stiffness, and damping. Sound Transmission Loss (STL) represents the amount of sound, in decibels (dB), that is isolated by a material or partition in a particular octave or 1/3 octave frequency band. In reality, there is a limit for increasing the mass, or the thickness of glass, and also for controlling stiffness due to the limit of glass design. To increase damping effectively and obtain good sound attenuation, laminated glass is used with a viscoelastic plastic interlayer that changes vibration energy into heat energy.

The human ear can hear sounds in the frequency range from 20 Hz to 20,000 Hz, and it is especially sensitive to sounds in the range of 1,000 Hz to 4,000 Hz. In case of a 4mm thick single glass plate, the frequency range for its coincidence dip is around 3,000 Hz. Wind noise comes from air blowing across the car body and is transmitted through glass parts, which then increase the interior noise level. This noise mainly includes high frequency sounds around 1,000 Hz to 5,000 Hz. Multi-layer acoustic PVB interlayer shows the highest STL value over monolayer acoustic PVB and normal PVB interlayer, especially in the coincidence dip range of 1,000 to 4,000 Hz. Therefore, high frequency sounds like wind noise from outside is effectively blocked by a multi-layer acoustic PVB interlayer. Special acoustic PVB interlayer, acoustic film has been adopted by several automobile manufacturers not only for high-end luxury vehicles but also for mid-class passenger cars. It achieves a quieter interior. Because of these acoustic properties, the manufactures can reduce the weight of the vehicle by using thinner (normally acoustically inferior) glass, which in turn results in better fuel efficiency.

Style and Taste

A car is, for many people, a reflection of their desired image or style, expressing an element of who they are and what they enjoy. And the car’s glass is an important visual component of this. Some people prefer the privacy of darkly tinted glass (or the perceived “VIP image” that goes with it), others like more light and openness. Many of these selections for the average driver are predicated upon cost.

Visual light and aerodynamic design requires glazed surfaces of increasingly complex geometries, which can be a real manufacturing challenge to ensure durability and perfect vision. Manufacturers are therefore continuously developing advanced glass shaping techniques which allow for the bending and shaping of the glass to offer car makers the freedom to achieve their design and style concepts whilst keeping a watchful eye on ever increasing tooling costs.

Colorants and colours

Some of the most-used colorants and the colours they produce are listed below:

Iron – Green, brown, blue

Manganese – Purple

Chromium – Green, yellow, pink

Vanadium – Green, blue, grey

Copper – blue, green, red

Cobalt – blue, green, pink

Nickel – yellow, purple

Titanium – purple, brown

Cerium – yellow

Selenium – pink, red

Gold – Red

Sulphide – yellow

Carbon & Sulphur – amber, brown

Dark tinted glass keeps the interior cool by absorbing solar energy and at the same time offers privacy for passengers in the back of the car (dark tinted glass is not permitted for the driver and forward-passenger windows, or of course for the windscreen). Dark tinted glass is available in several colours and each colour in several shades from lighter to very dark. The values shown are percentages of light transmission.

Switchable glazing, which responds to varying electrical conditions with correspondingly different colour properties, allows for the creation of a “customized” interior ambience. Via a simple dial, a driver or passengers can control the amount of light entering the vehicle – blocking anywhere from 4% to 40%. Heat from sunlight can be reduced by anywhere from 2% to 20%. One can select a lighter tint on cloudy days, and then darken it when the sun reappears, or simply change the lighting to suit one’s mood or create an appearance appropriate for the occasion.

Glass in photovoltaic applications

Photovoltaics – how it works

Conventional photovoltaic cells are electronic components based on silicon, a semiconductor material. It absorbs photons (constituents of solar rays) converting their energy into electrical particles (electrons). These charges are collected on the front and rear of the cell. The tension this creates generates an electrical current. Each cell only produces a limited quantity of electricity (≈ 0.5 volt). The cells are assembled in modules and panels, which are themselves connected in series.

Photovoltaic technologies are used to convert solar energy directly into electricity. There are many different technologies available to suit various requirements, from domestic systems to utility scale. Photovoltaic panels come in various shapes and colours offering flexibility for design integration. Unfortunately in the automotive industry, the return on investment (ROI) has only been around 10%, not sustainable for production.

The most common photovoltaic technology is based on crystalline silicon solar cells. In this application glass acts as a protective outer layer, while transmitting the solar light to the photovoltaic cells interconnected underneath.

Other photovoltaic technologies include thin film where solar cells are deposited as a sequence of thin films on glass. In these technologies, transparent conductive coated glass can be used as the front glass upon which the films are grown. The conductive coating not only allows light through to the photoactive films, but also conducts the generated electricity out of the modules.

More books and blogs from Lyn R. Zbinden: Glass Engineering: Design Solutions for Automotive Applications: http://books.sae.org/r-433/,