Designing Glass for Style© by Lyn Zbinden

Designing Glass for Style© by Lyn Zbinden

Main Types of Glass and Alternative Materials used in Automotive

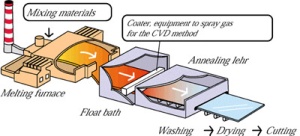

Today, flat (float) glass comes in many highly specialised forms intended for different products and applications. Flat glass produced by way of the float process is often further processed to give it certain qualities or specificities. In this way, the industry can meet the various requirements and needs of the automotive and subspecialties like solar absorption or reflectance.

Annealed glass

Annealed glass is the basic flat glass product that is the first result of the float process. It is common glass that tends to break into large, jagged shards. It is used in some end products and often in double-glazed windows. It is also the starting material used to produce more advanced products through further processing such as laminating, toughening, coating, etc.

Toughened glass

Toughened glass is treated to be far more resistant to breakage than simple annealed glass and to break in a more predictable way when it does break, thus providing a major safety advantage in almost all of its applications.

Toughened glass is made from annealed glass treated with a thermal tempering process. A sheet of annealed glass is heated to above its “annealing point” of 600°C; its surfaces are then rapidly cooled while the inner portion of the glass remains hotter. The different cooling rates between the surface and the inside of the glass produces different physical properties, resulting in compressive stresses in the surface balanced by tensile stresses in the body of the glass.

These counteracting stresses give toughened glass its increased mechanical resistance to breakage, and are also, when it does break, what cause it to produce small, regular, typically square fragments rather than long, dangerous shards that are far more likely to lead to injuries. Toughened glass also has an increased resistance to breakage as a result of stresses caused by different temperatures within a pane.

Toughened glass has extremely broad applications in products for both buildings and, automobiles and transport, as well as in other areas. Car windshields and windows, glass portions of building facades, glass sliding doors and partitions in houses and offices, glass furniture such as table tops, and many other products typically use toughened glass. Products made from toughened glass often also incorporate other technologies, especially in the building and automotive and transport sectors.

Laminated glass

Laminated glass is made of two or more layers of glass with one or more “interlayers” of polymeric material bonded between the glass layers.

Laminated glass is produced using one of two methods:

1) Poly Vinyl Butyral (PVB) laminated glass is produced using heat and pressure to sandwich a thin layer of PVB between layers of glass. On occasion, other polymers such as Ethyl Vinyl Acetate (EVA) or Polyurethane (PU) are used. This is the most common method.

2) For special applications, Cast in Place (CIP) laminated glass is made by pouring a resin into the space between two sheets of glass that are held parallel and very close to each other.

Laminated glass offers many advantages. Safety and security are the best known of these, so rather than shattering on impact, laminated glass is held together by the interlayer. This reduces the safety hazard associated with shattered glass fragments, as well as, to some degree, the security risks associated with easy penetration. But the interlayer also provides a way to apply several other technologies and benefits, such as colouring, sound dampening, and resistance to fire, ultraviolet filtering and other technologies that can be embedded in or with the interlayer.

Laminated glass is used extensively in building and housing products and in the automotive and transport industries. Most building facades and most car windscreens, for example, are made with laminated glass, usually with other technologies also incorporated.

Coated

Surface coatings can be applied to glass to modify its appearance and give it many of the advanced characteristics and functions available in today’s flat glass products, such as low maintenance, special reflection/transmission/absorption properties, scratch resistance, corrosion resistance, etc.

Coatings are usually applied by controlled exposure of the glass surface to vapours, which bind to the glass forming a permanent coating. The coating process can be applied while the glass is still in the float line with the glass still warm, producing what is known as “hard-coated” glass. Alternatively, in the “off-line” or “vacuum” coating process, the vapour is applied to the cold glass surface in a vacuum vessel.

Extra clear glass

Extra clear glass is not the result of processing of annealed glass, but instead a specific type of melted glass. Extra clear glass differs from other types of glass by its basic raw material composition. In particular, this glass is made with very low iron content in order to minimise its sun reflection properties. It therefore lets as much light as possible through the glass. It is most particularly of use for solar energy applications where it is important that the glass cover lets light through to reach the thermal tubes or photovoltaic cells. Anti-reflective properties can be further increased by applying a special coating on the low-iron glass. It can also be used in windows or facades as it offers excellent clarity, which allows occupants to appreciate true colours and to enjoy unimpaired views.

Polycarbonate

As automakers seek improved fuel efficiency, polycarbonate’s lightweight, impact-resistant properties can reduce vehicle weight while enabling sleek curves in modern designs. Not only do polycarbonates reduce the weight of vehicle components by up to 50%, but also help cutting fuel consumption and CO2 emissions, while keeping strength, safety and style.

Concept car ZaZen

Lightweight materials may find exciting opportunities in the automotive industry as a means of increasing fuel efficiency. With 75% of fuel consumption relating directly to vehicle weight, potential weight reductions that result in improved price-performance ratio promote use of lightweight materials. The automotive industry can expect an impressive 6-8% improvement in fuel usage with only 10% reduction in vehicle weight. This translates into a reduction of around 20 kg of CO2 per kilogram of weight reduction over the vehicle’s lifetime. Lighter vehicles facilitate easier braking, reduced collision impact overall vehicle performance and superior driving experience. One of the key plastics used in automotive sector is polycarbonate (PC). PC has dominated the market for vehicle headlamp covers for 15 years, and now it challenges glass in windows. The primary advantages of PC automotive glazing are lowered weight and associated CO2 emissions reductions along with greater styling freedom and simpler functional integration. The main drawback to a PC is weathering, resistance to scratch, positions on the vehicle where PC can be used by federal standards and cost. By the time you apply a hard coat, any potential savings derived from weight is now lost due increased piece price cost which can be as much as 4:1.